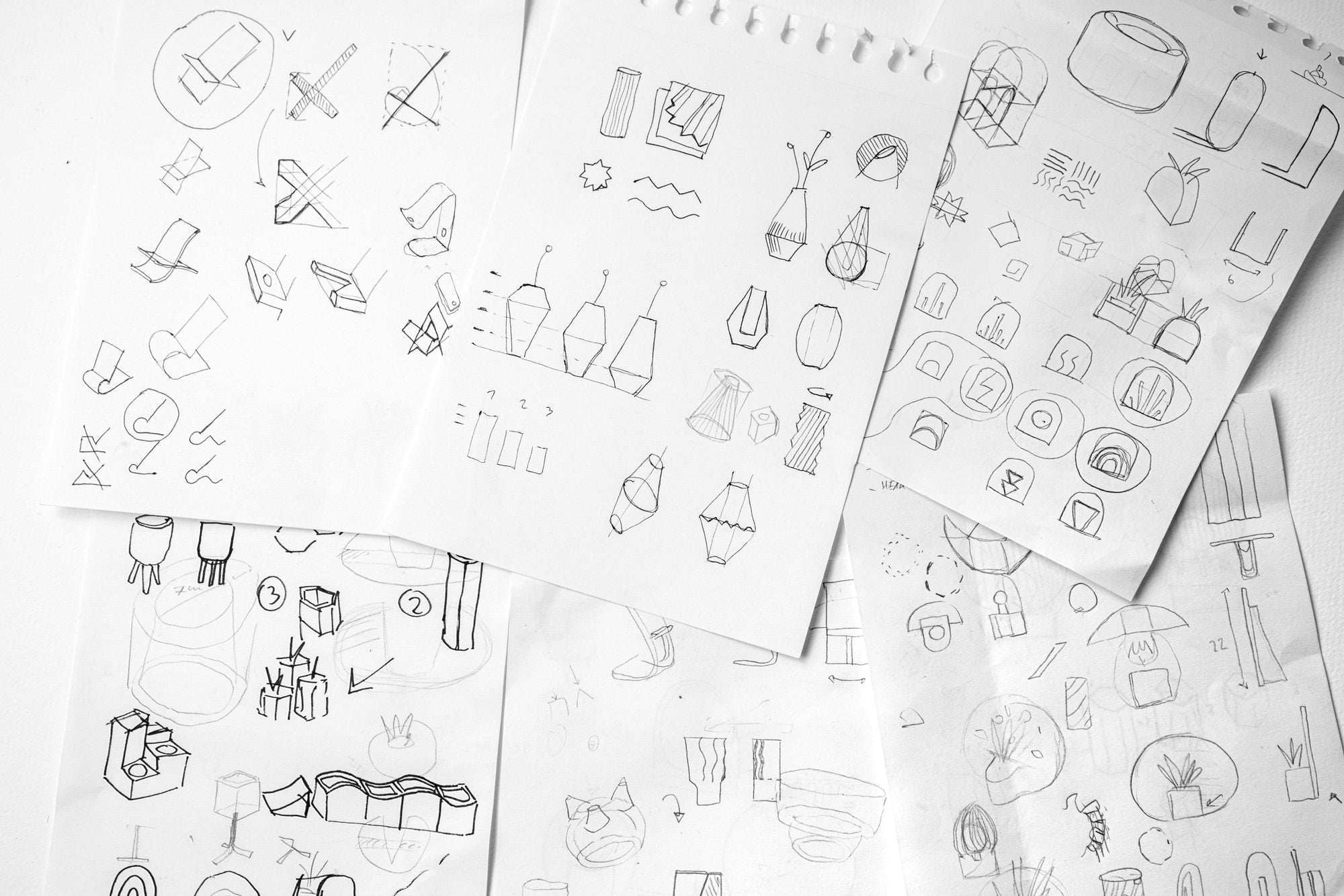

The process

To be as transparent as possible, you will find here the necessary steps for the manufacture of COPO objects.

From idea to realization

At Copo, everything is done by hand. We design all the models in-house, then produce them in 3D. After a prototyping stage, we validate the model, then put it in the catalog.

Raw materials

To print additively, we use a filament made from corn starch and wood powder. The result is a 100% natural, healthy and plastic-free material.

3D printing

3D printing technology became popular a few years ago. While being revolutionary and little known, it above all makes it possible to create unusual objects in small series, consuming very little.